Mecadaq Group offers machining and assembly capacities to the largest customers in the aerospace, automotive and home automation sectors.

Our strengths come from the synergy of the five Group industrial sites, benefiting from a modern and efficient machine park. The Group invests about 7% of its turnover in replacing or improving production equipment.

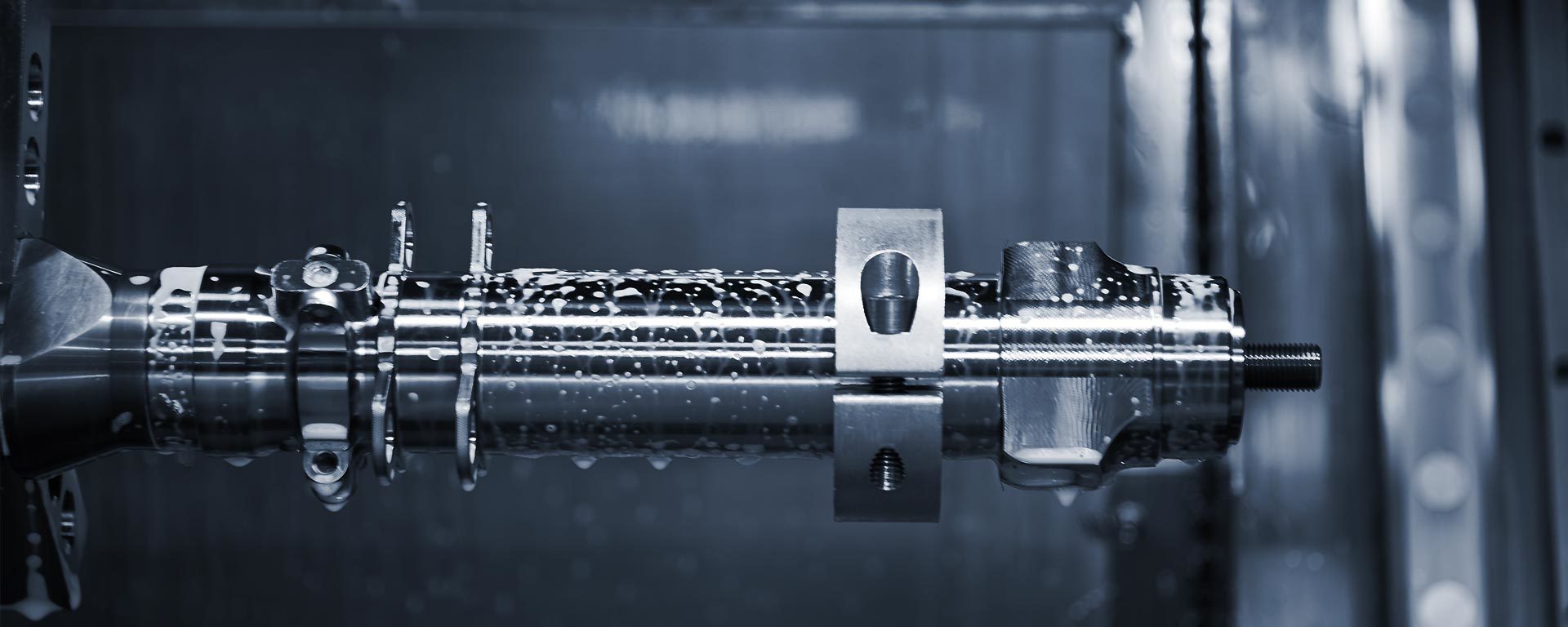

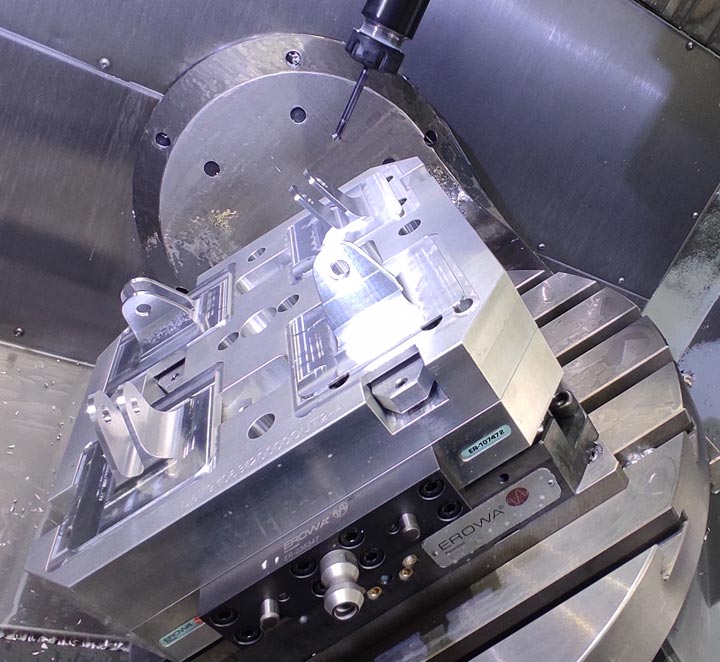

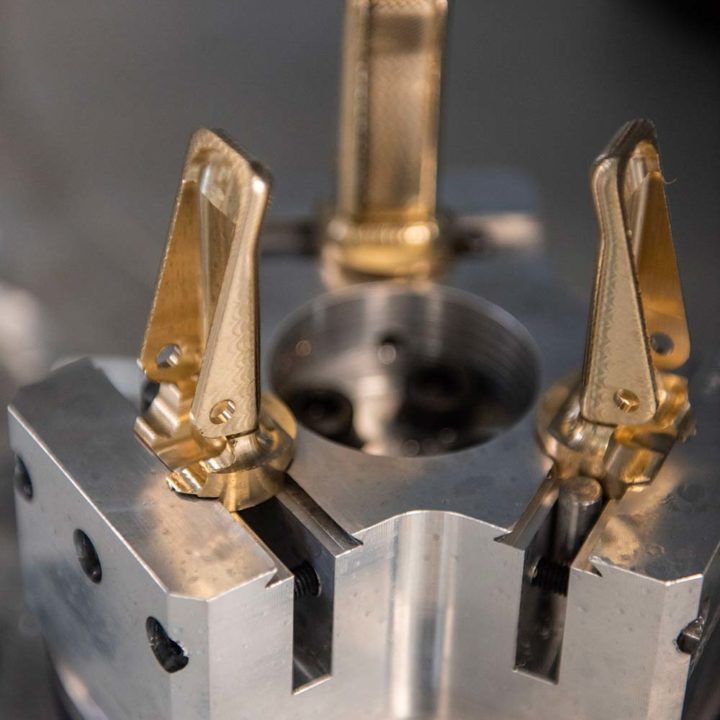

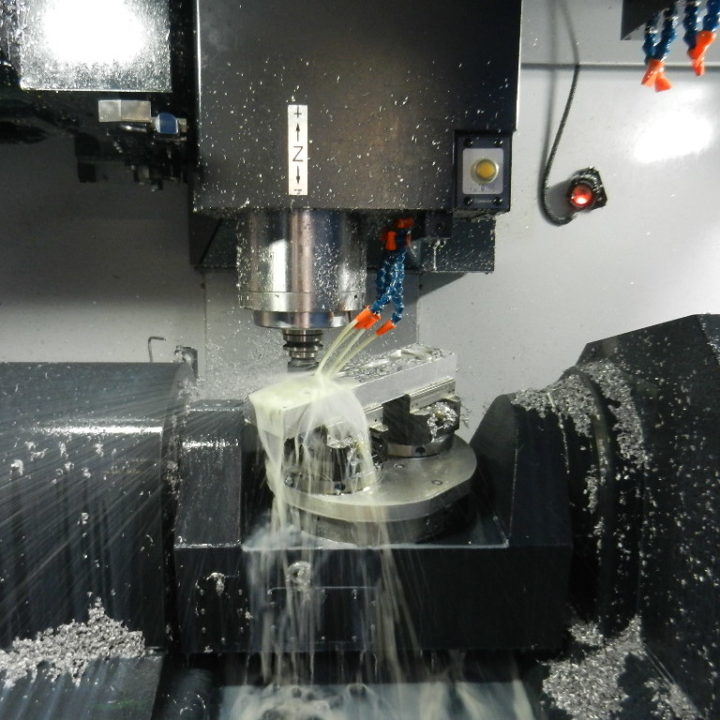

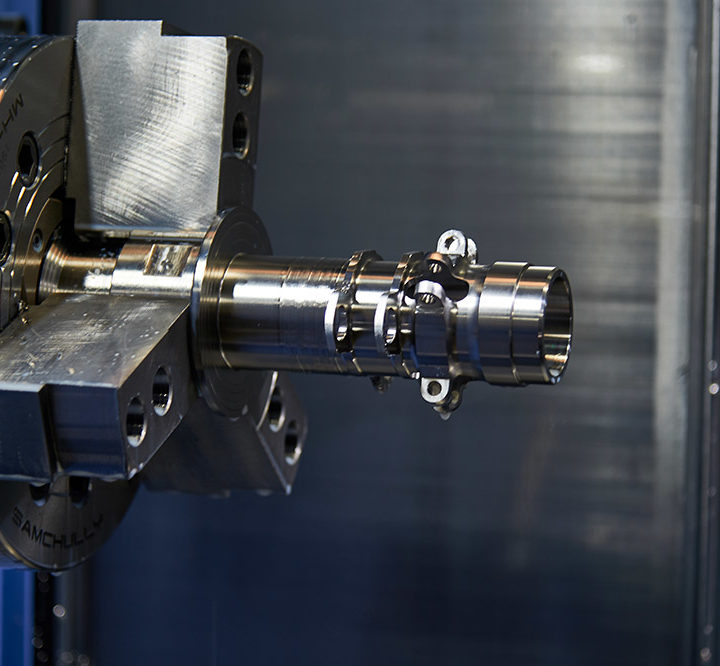

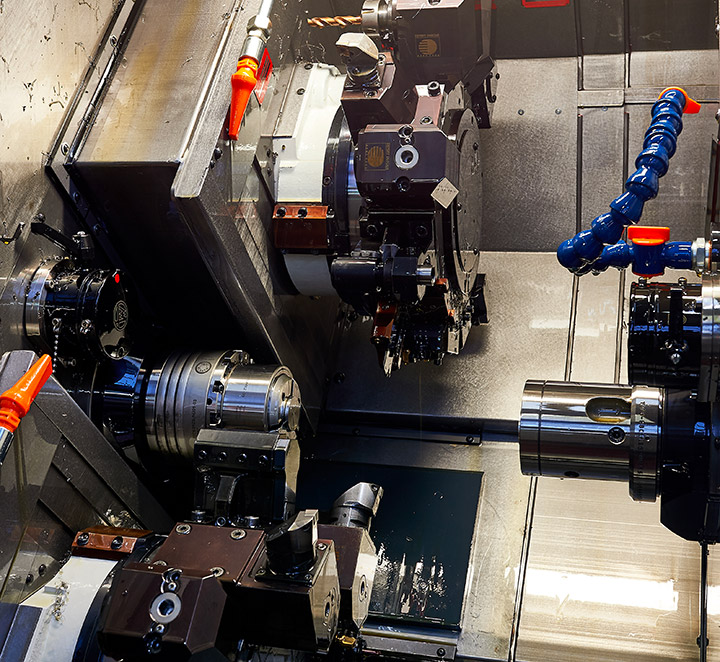

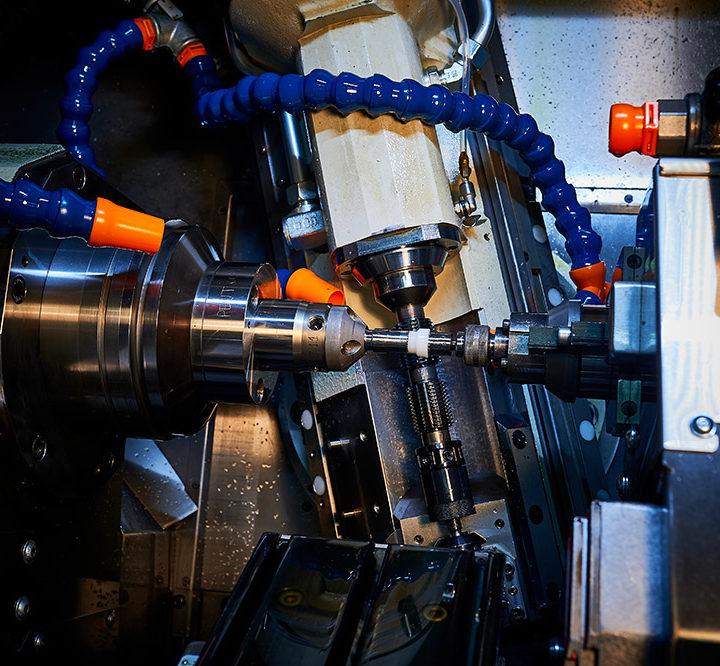

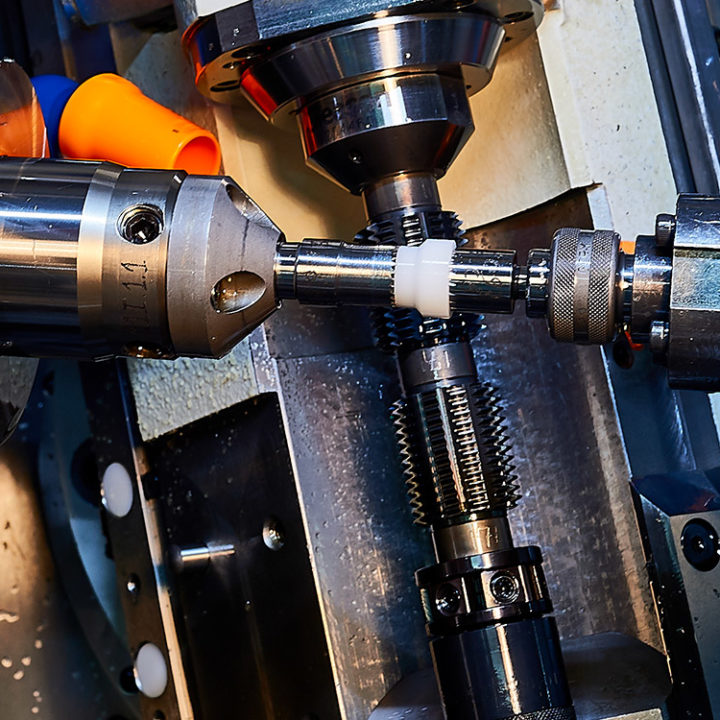

Thanks to 130 CNC machines, the Group is able to support its customers with all their machining needs, from 5-axis milling to gear cutting and turning.

Our core business is based on:

- Storage and cutting of materials

- Machining of complex parts in hard metals and aluminum, 4 and 5 axis

- Turning /Bar Turning/ Mill-Turning

- Gear cutting

Our goal is to meet all of our customers’ technical and cosmetic requirements. Mecadaq Group has also developed a robotic finishing process to guarantee perfect execution to the specifications of our partners. Boeing’s Passenger B787 door handles are a prime example of specifications for a special cosmetic finish that our finishing process can support.