Mecadaq Group is made up of five industrial sites : four in France and one in the United States.

Over the years, the Group has relied on the one hand, on the development and diversification of its machining skills and. on the other hand, on the deployment of automation of its means of production.

Mecadaq Group has developed a talented team in charge of industrialization, composed of 15 collaborators spread over our different sites, receiving customer requests and specifications, and analyzing them to formulate the best and the most efficient proposal adapted to your needs.

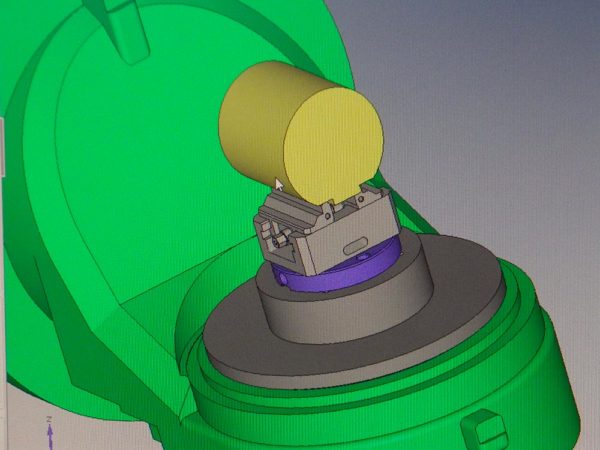

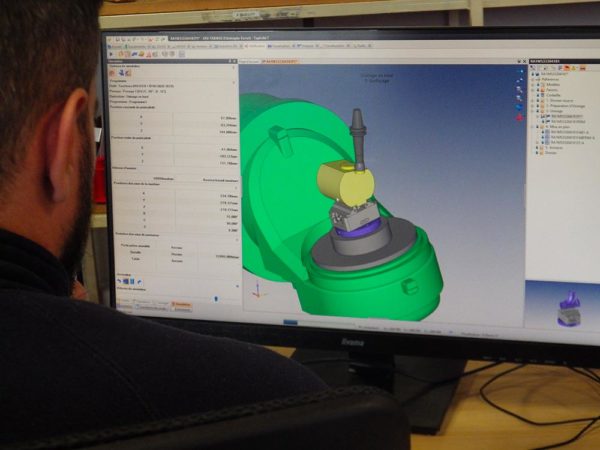

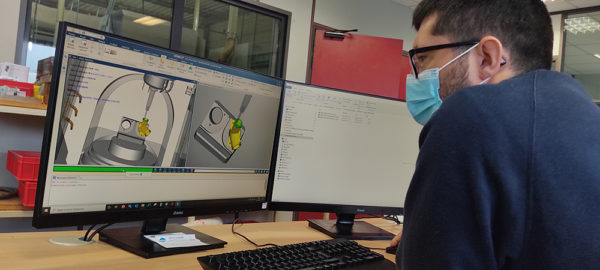

Regularly trained in updates to our industrialization software, our technicians – each with their own area of expertise – can program water jet cutting, turning, gear cutting and up to 5-axis and multiple axis machining.

Equipped with Vericut, CATIA, Pro Engineer and Top Solid from Missler, all these tools allow us to read, set up and check parts easily and digitally; a precious time saving measure for both customers and operators.

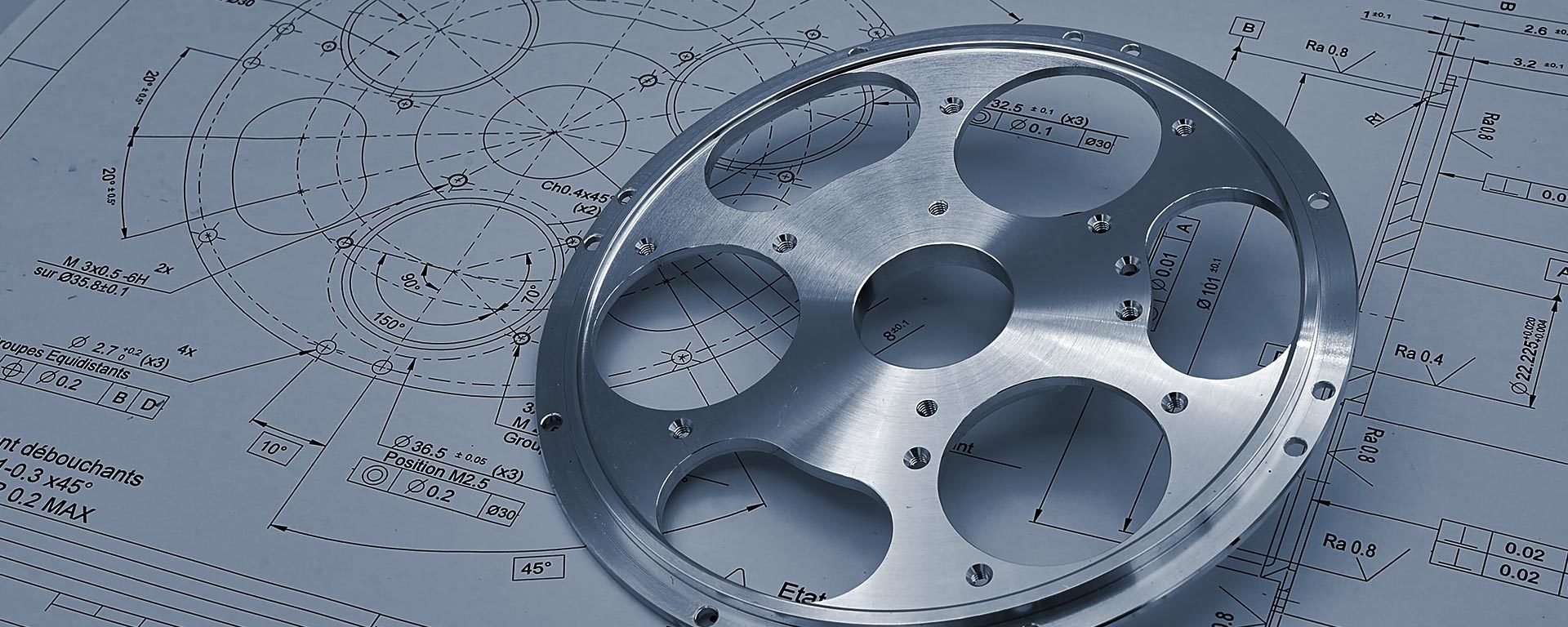

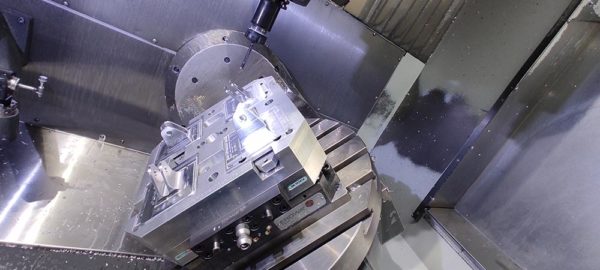

As a built-to-print subcontractor, we know how create the tooling that’s best adapted to the part requested. Our expertise transforms our customers’ 3D plans into the finished product. We master the entire process from A to Z.

Having our own industrialization department within the company is a key advantage that allows our customers to interact with the same team through the entire manufacturing process. This allows us to manage every aspect of your project and to propose the most efficient solutions in terms of cost, planning, deadline and means of production.