Mecadaq Group se compose aujourd’hui de 5 unités de production, 4 en France, et une aux Etats-Unis.

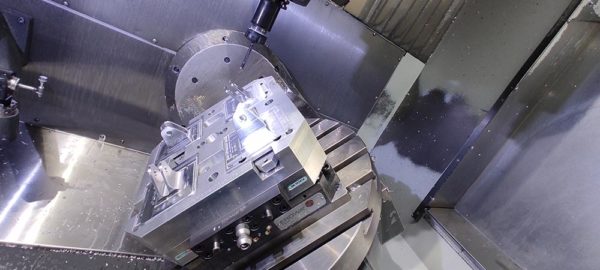

Au fur et à mesure des années, le Groupe a misé, d’une part, sur le développement et la diversification de ses compétences d’usineur et, d’autre part, sur le déploiement d’une automatisation de ses moyens de production.

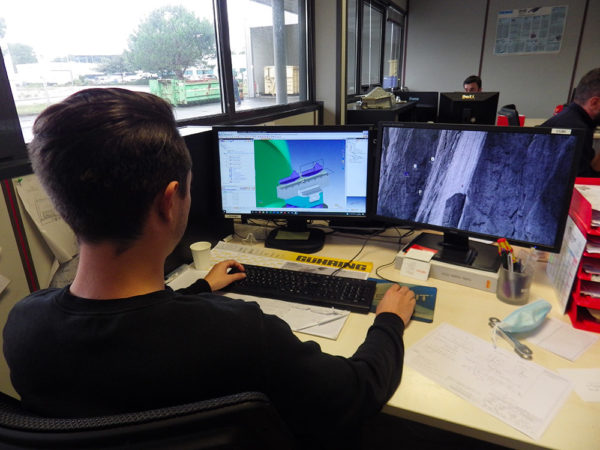

Mecadaq Group a développé une importante équipe en charge de l’industrialisation, composé de près de 15 collaborateurs répartis sur les différents sites, réceptionnant vos demandes et spécifications, les analysant pour formuler la proposition la plus efficace et adaptée à vos besoins.

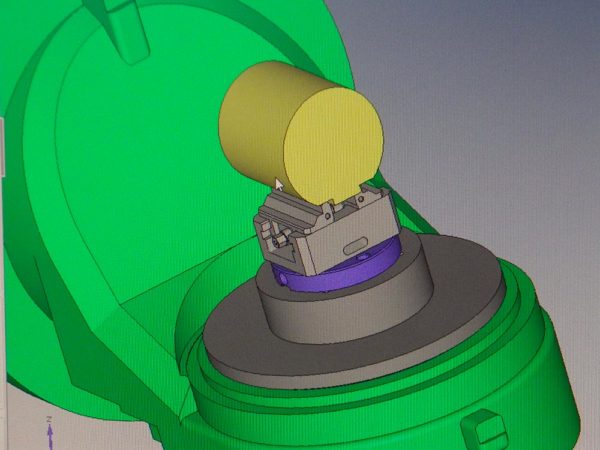

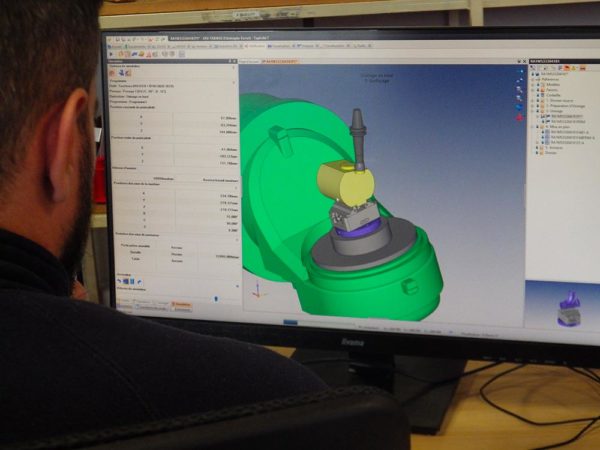

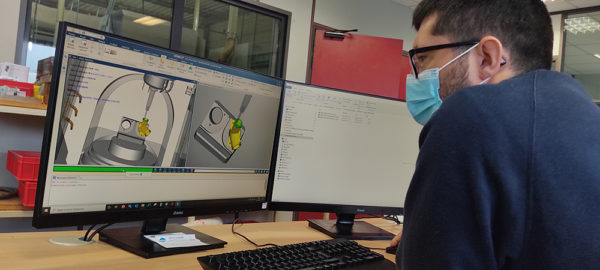

Régulièrement formés aux évolutions de nos logiciels d’industrialisation, nos techniciens, avec chacun leurs spécificités, sont en capacités de programmer de la découpe jet d’eau, du tournage, taillage d’engrenage, jusqu’à l’usinage 5 axes et multiaxes.

Equipé de Vericut, CATIA, Pro Engineer, et Top Solid de Missler, ces outils nous permettent une lecture, une mise en place et une vérification facilitée et digitalisée ; un gain de temps précieux pour les clients comme pour les opérateurs.

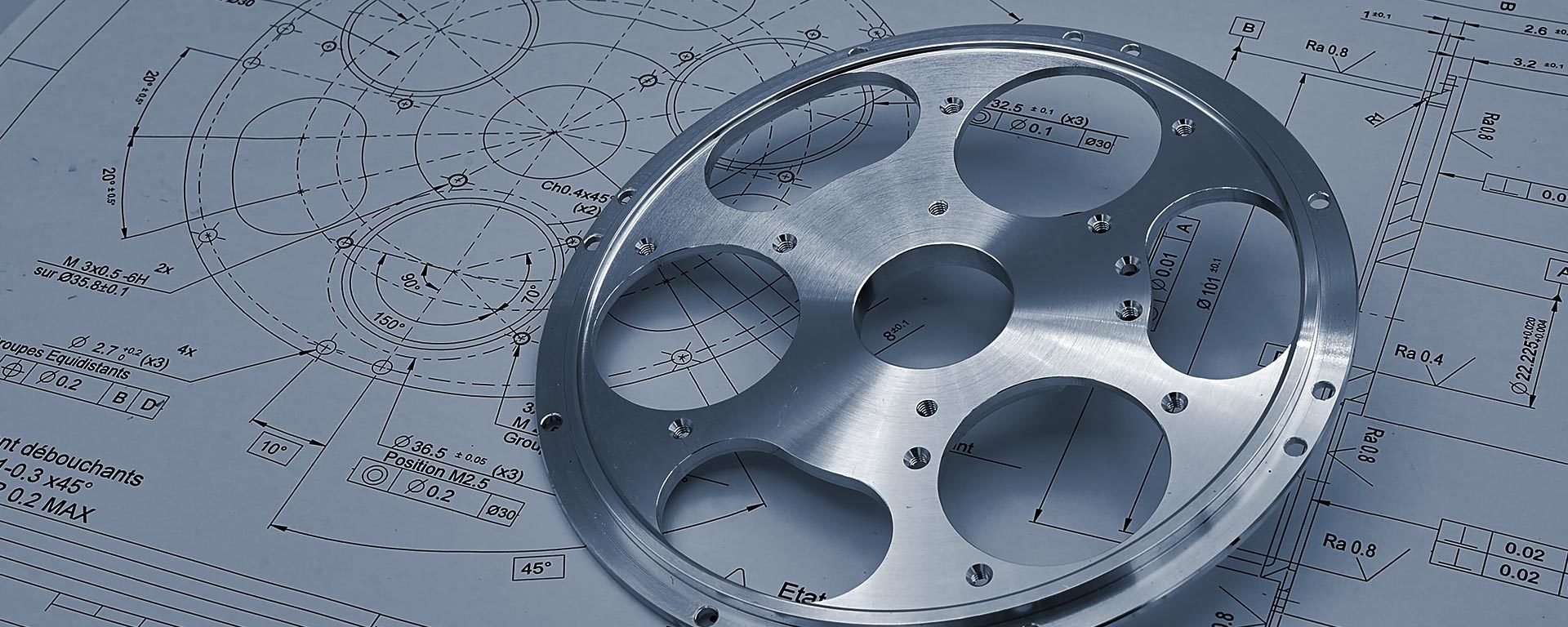

Sous-traitant built to print, nous savons créer l’outillage adapté à la réalisation de la pièce demandée. Notre expertise transforme les plans 3D de nos clients en produit fini. Nous maîtrisons le processus de création de A à Z.

Avoir notre propre bureau des méthodes au cœur de l’entreprise est un avantage conséquent ; cela permet à nos clients d’interagir avec le même interlocuteur tout au long du process et à chaque étape de la fabrication. Ainsi, nous pouvons suivre votre projet, dans sa globalité et vous proposer les solutions les plus efficaces en termes de coût, de planning, de délai et de moyens de production.